Introduction of Automatic Veneer Splicing Machine

Automatic Veneer Splicing Machine – Pappor Plus is a device used in the woodworking industry to join thin veneer panels together, forming a larger veneer sheet that caters to a variety of production requirements.

► Model: RAPPOR PLUS

► Trademark: KINGWOODMAC

Features of automatic veneer splicing machine

- Gear drive system increases stability

- Divided into 6 heating sections, temperature can be controlled independently

- Automatic veneer machine componets are manufactured abroad, so they have long life and durability

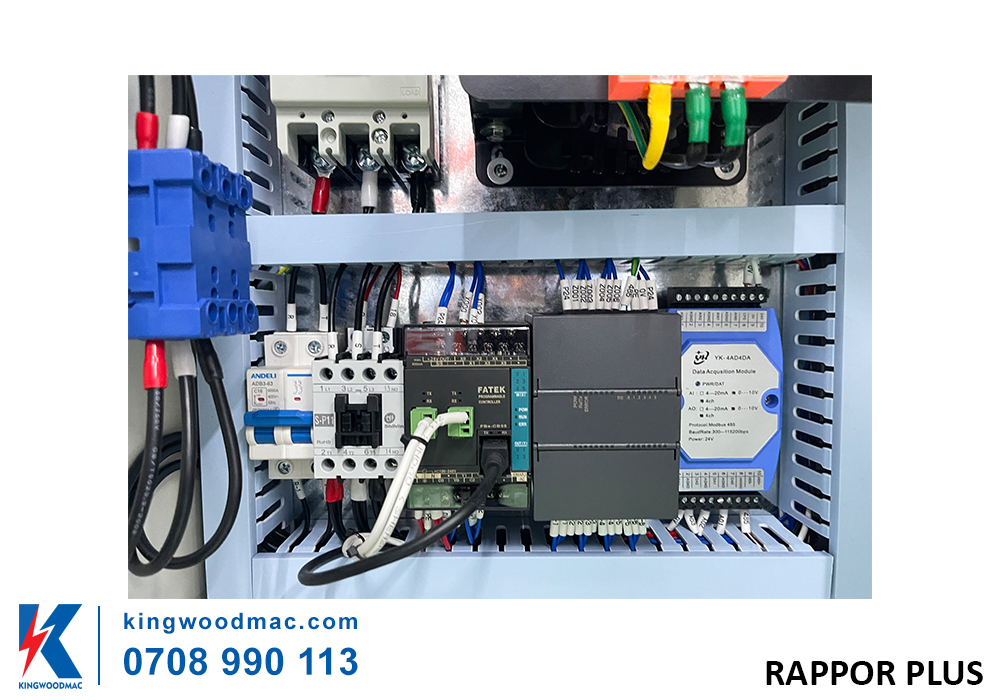

- This veneer machine is operated by a fully automatic PLC control system with gear drive system

- Patented thickness setting system, simple and stable operation

Specifications of Rappor Plus

| Veneer thickness | 0.3 – 4.0 mm < 0.3 mm (Depending on strength of veneer) |

| Veneer width | > 50 mm |

| Min. Veneer length | 300 mm |

| Glue | Urea formaldehyde solution |

| Feeding speed | 5 – 50 m/min |

| Heating temperature | 80 °C – 180 °C |

| Power supply | 7.5 kW |

| Compressed air | 6 kg/cm² |

| Net weight | 1500 kgs |

| Machine size | 2150 x 2000 x 1650 mm |

| In feed and out feed tables size | 2440 x 1220 mm |

Note: The technical parameters of the veneer seaming machine can be adjusted within allowable limits for better suitability without affecting the structure and function of the machine.

Automatic Veneer Splicing Machine Details

Contact information for Automatic veneer splicing machine Rappor Plus

For more details about the automatic veneer splicing machine, please call the following information directly for the fastest support from staff and consultants.

- Hotline: 0708 990 113

- Email: kingwoodmac@gmail.com

- Address: 401 To Ngoc Van, Thanh Xuan Ward, District 12, Ho Chi Minh City

- Website: kingwoodmac.com

Đánh giá

Chưa có đánh giá nào.